Introduction:-

Centrifugal pumps are the most preferred hydraulic pumps used in domestic and industrial world.Centrifugal pumps are used to transport fluids

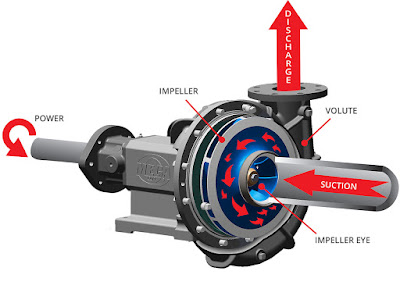

by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from where it exits

Working Principle :-

Centrifugal pumps rely on centrifugal force as the fundamental principle by which they operate. Centrifugal force affects an object or material moving in a circular pattern by causing it to pull away from the central axis or center point of the path along which it travels. This force can be used to regulate the pressure and motion within a pumping unit, and when applied in combination with a number of other centrifugal pumping principles, forms an integral part of hydraulic mechanisms.

In centrifugal pump there is an impeller. It has a series of curved vanes fitted inside the shroud plates. The impeller is always immersed in the water. When the impeller is made to rotate, it makes the fluid surrounding it also rotate. This imparts centrifugal force to the water particles, and water moves radially out.

Since the rotational mechanical energy is transferred to the fluid, at the discharge side of the impeller, both the pressure and kinetic energy of the water will rise. At the suction side, water is getting displaced, so a negative pressure will be induced at the eye. Such a low pressure helps to suck fresh water stream into the system again, and this process continues.

Centrifugal pumps are the most preferred hydraulic pumps used in domestic and industrial world.Centrifugal pumps are used to transport fluids

by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from where it exits

|

| Centrifugal Pump |

Centrifugal pumps rely on centrifugal force as the fundamental principle by which they operate. Centrifugal force affects an object or material moving in a circular pattern by causing it to pull away from the central axis or center point of the path along which it travels. This force can be used to regulate the pressure and motion within a pumping unit, and when applied in combination with a number of other centrifugal pumping principles, forms an integral part of hydraulic mechanisms.

In centrifugal pump there is an impeller. It has a series of curved vanes fitted inside the shroud plates. The impeller is always immersed in the water. When the impeller is made to rotate, it makes the fluid surrounding it also rotate. This imparts centrifugal force to the water particles, and water moves radially out.

|

| Impeller |

Since the rotational mechanical energy is transferred to the fluid, at the discharge side of the impeller, both the pressure and kinetic energy of the water will rise. At the suction side, water is getting displaced, so a negative pressure will be induced at the eye. Such a low pressure helps to suck fresh water stream into the system again, and this process continues.

|

| Working of centrifugal pump |

No comments:

Post a Comment